1301 Charleston Regional Pkwy B, Charleston, SC 29492

Case Studies

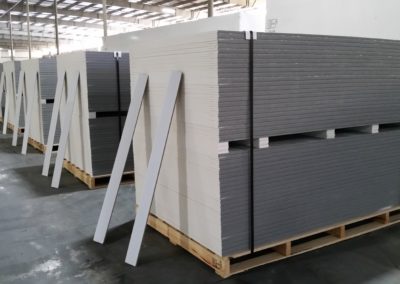

Small Parts for a Massive Project

Problem:

With significant export sales of their commercial grade gypsum board to countries all over the globe a reliable and responsive partner with a high level of service quality is a must-have for our client.

An ordinary warehouse operation isn’t an option though – before the material can be loaded for export a significant amount of product manipulation must be performed to maximize the sheet count in each container, and ensure that the product arrives at foreign construction sites in perfect condition, ready for installation, in a manner that can be handled at a construction jobsite. And in such a competitive market, with customers placing orders based on cost changes in the order of cents per sheet, an economic solution can be make-or-break.

Solution:

Our client chooses Dockside for our unique capabilities and service performance:

- Ability to handle order-based and seasonal fluctuations with ease

- Ability to manufacture product packaging in-house

- Ability to optimize product consolidation, maximizing sheet count per container (reducing landed cost per sheet) whilst accounting for over-the-road trucking and shipping container weight limit considerations

- Expertise in manipulating, handling, loading and securing such a fragile commodity without incurring damage

Results:

- 2,240 TEUs per year

- 915,000 sheets / 290,000 SF

- 100% on time shipping

- 100% shipping accuracy

- Zero damage

Services Used:

- IT/Visibility

- Shared warehousing

- Transloading

- Value Added Services

- Packaging

CALL US: 844-395-7447

Charleston, SC

4756 U.S. Highway 78

Saint George, SC 29477

1 Immigration St

Charleston, SC 29403

912 Commerce Cir

Hanahan, SC 29410

Houston, TX

7449 E Orem Dr

Houston, TX 77075

Solutions

Markets

Support

Dockside

Let's Work Together

Dockside: The Measurable Difference

844-395-7447

1 Immigration St

Charleston, SC 29403

912 Commerce Cir

Hanahan, SC

4756 U.S. Highway 78

Saint George, SC 29477

DOCKSIDE HOUSTON

844-395-7447

7449 E Orem Dr

Houston, TX 77075